Thin Film Evaporators

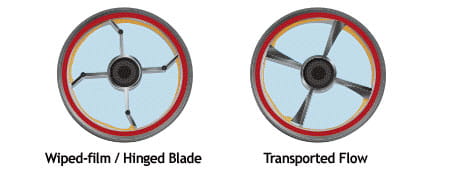

An LCI agitated thin film evaporator (TFE) or wiped film evaporator (WFE or "wiffe") provides short residence time and open, low pressure drop configuration, allowing continuous, reliable processing of many heat sensitive, viscous, or fouling materials without product degradation.