- Home

- Powder Handling

- Laboratory Equipment

Basket Granulator BR-150 Lab Extruder

Basket Granulator BR-150 Lab Extruder

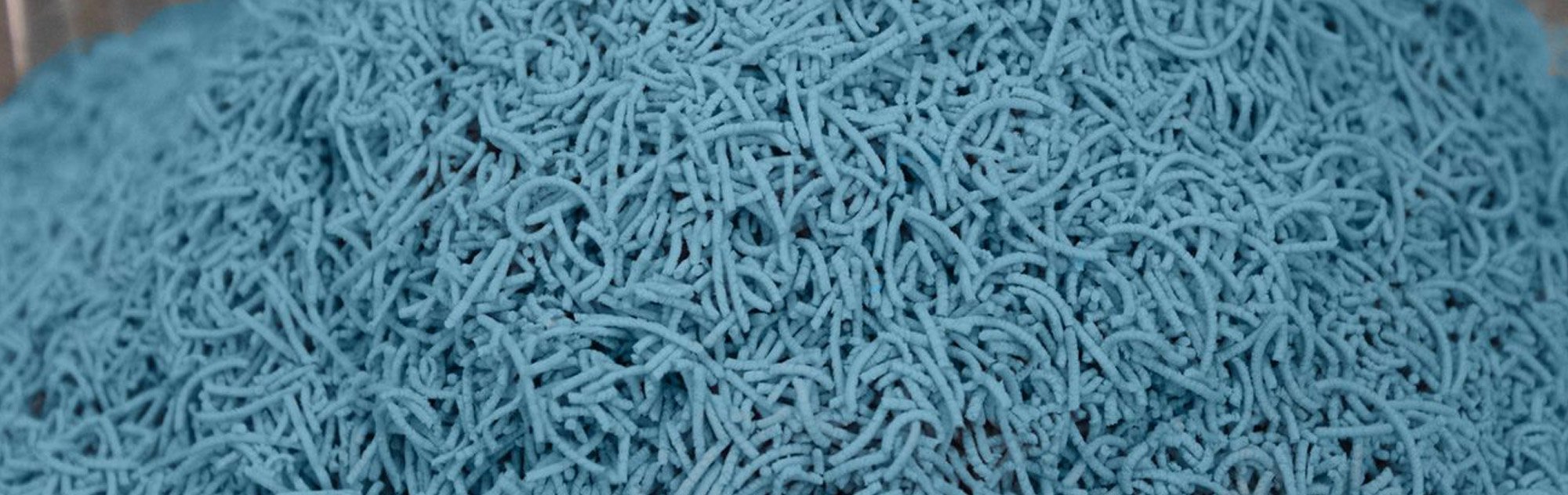

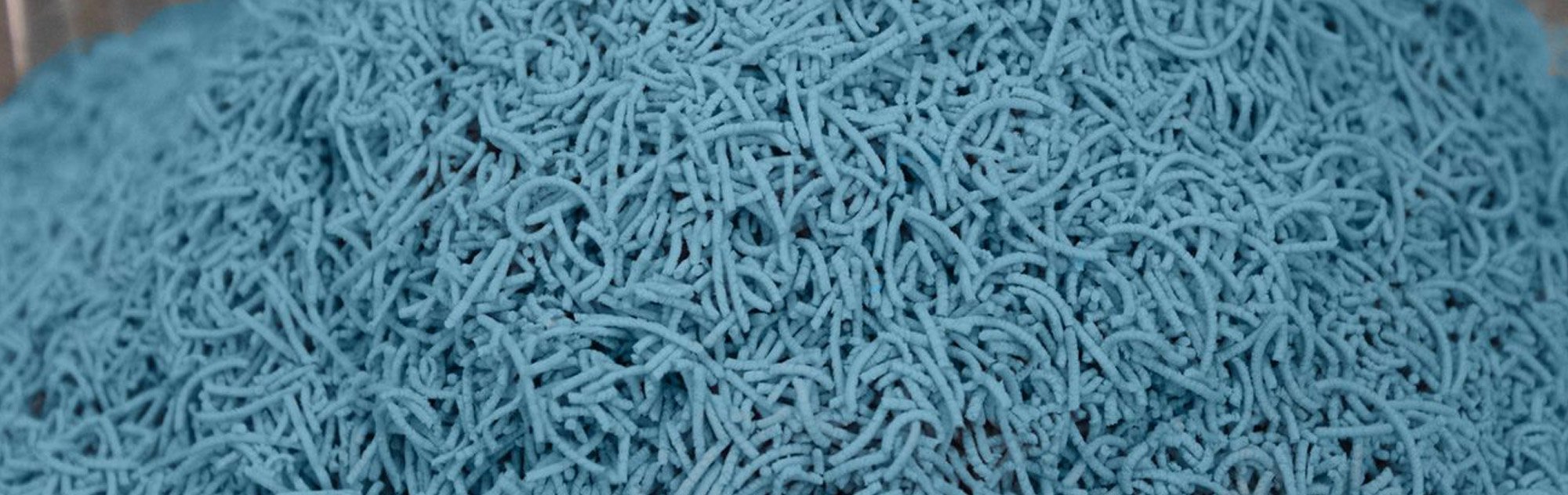

Laboratory basket extruder to create granules from 0.6mm to 1.2mm in diameter. The BR-150’s size and unique features allow it to evaluate small batch sizes, while generating product indicative of a full-scale basket production system.

The BR-150 can be easily assembled with the desired screen and prepared for extrusion. A wet mixture is separately prepared manually or in a small batch mixer, also available from LCI. The wet mixture is manually fed into the feed hopper and falls by gravity onto the pressure blade. The pressure blade is a scraper-like device that prevents bridging at the hopper discharge and directs the material into the extrusion zone. The extrusion blades gently wipe the material through the screen yielding well formed extrudates.

Features and Benefits

- Gravity fed device with pressure blade and two extrusion blades

- Lowest pressure extruder available

- 150 mm diameter basket screens

- Capable of extruding granules from 0.6 mm to 1.2 mm in diameter

- GMP design with 316SS contact parts

- 0.5 hp 230VAC/3/60 variable speed drive for extrusion blades

- 0.2 hp 230VAC/3/60 motor to drive pressure blade

- Separate stainless steel control panel with PLC, Variable Frequency Drive, and touch screen