- Home

- Sludge Drying

- Thin Film Sludge Dryer

Thin Film Sludge Dryer How It Works

Thin Film Sludge Dryer - How It Works

How it works

Thin Film Sludge Dryers are thermal drying systems designed for sludge treatment at wastewater treatment plants or industrial wastewater treatment plants. Their purpose is to reduce sludge volume by decreasing the liquid content and increasing the solid content of sludge. This in turn reduces the volume and weight of sludge therefore significantly decreasing disposal costs or opening avenues for beneficial reuse.

These dryers are based on the same design principle of Thin Film Evaporators, only they evaporate water from sludge in place of evaporating components from liquids.

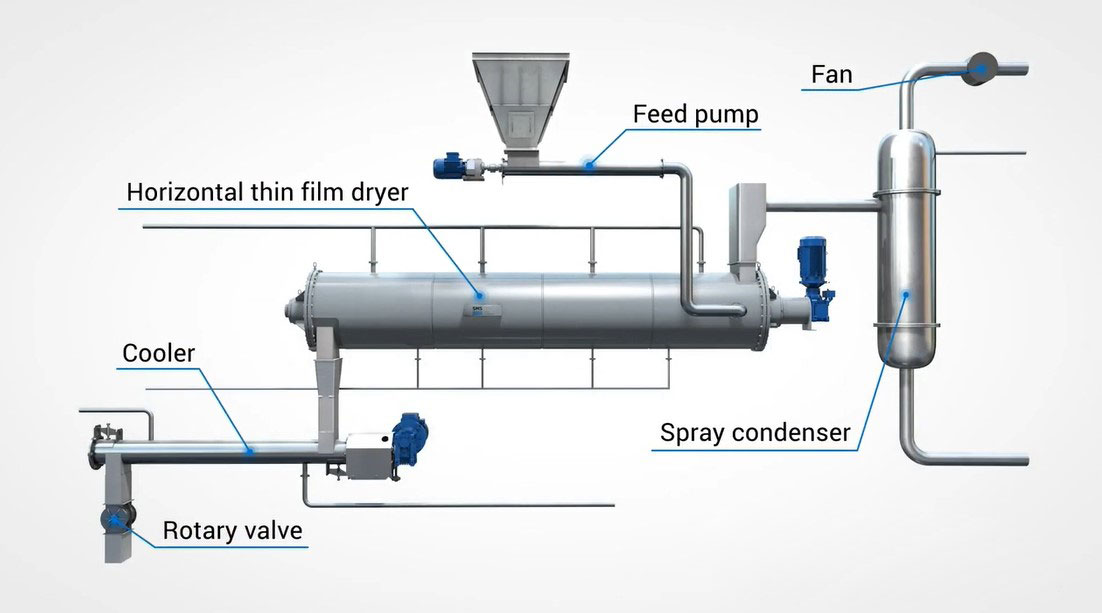

The Thin Film Sludge Dryer System Consists of

- Horizontal Thin Film Sluge Dryer

- Feed Pump

- Product Cooler (optional)

- Rotary Valve

- Spray Condenser

- Fan

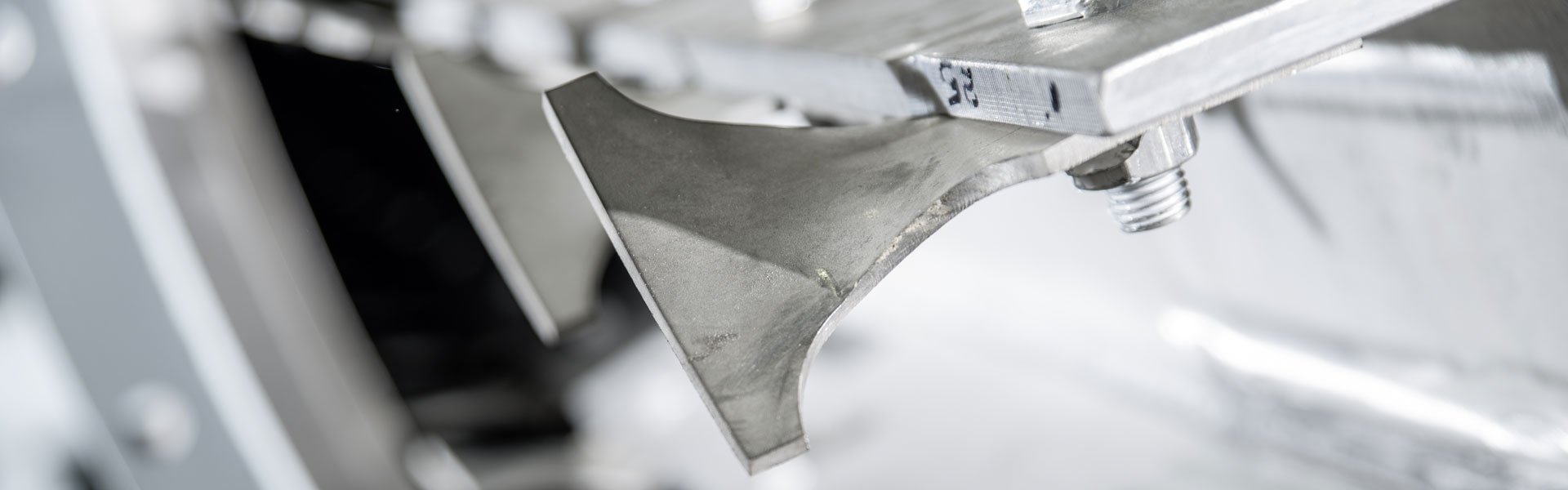

The Horizontal Thin Film Sludge Dryer consists of a

- Rotor with Blades

- Heating Jacket including

- Heating fluid

- Heating Surface

The operating principle of the Thin Film Dryer is simple. The sludge is pumped into the dryer where the rotating blades on the rotor convey and evenly spread the sludge into a thin film (1-3mm) against the outer heating surface. Heating fluid (steam, water, or thermal oil) flows on the outside of the heating surface and heat is indirectly transferred to the sludge film.

Moisture is released as the sludge is heated and flows counter current to the sludge flow out of the dryer to a condenser. The exhaust fan pulls the moisture through the system.

After a short residence time in the dryer, the dried sludge (anywhere from 30% to 90%+ DS) is conveyed out of the dryer and to a cooling screw, if required. The sludge is then ready to be conveyed for further processing.

Output examples of Dried Sludge